Over the last ten years I have taken several workshops in letterpress printing. But a workshop here, and one there has not made me competent or confident. I love the quality of letterpress, the slightly embossed type on the page, and the equipment, much the same as it was hundreds of years ago.

If you’re not familiar with letterpress, the process is one that was used to print the Gutenberg Bible in the 1400’s. Though printing of wood cuts was known and used, it was Johannes Gutenberg who invented moveable type that was set into lines of type, the moving bed in which the lines of print are set, and oil-based inks which began a revolution in mass printing for books, then newspapers and broadsides.

Now considered quaint by some, and elegant by others, letterpress allows artist book makers to control exactly where and how the type will land on the page. It also allows for using woodcuts, some monoprint techniques, and now the use of polymer plates for photographs and blocks of text without the lengthy setting of type that was needed in Gutenberg’s day. The edition of a book on a press can designed and produced by a professional printer, or by an artist wanting to create more of a handmade object but in multiples.

Maine Media Workshops has two Vandercook presses. To use them, I had to be vetted by taking a workshop in the letterpress process. I would add, the process, while not difficult, is complex. Like other multi-step processes, practicing and learning to trouble-shoot problems requires experience over time. They can also be learned with the help of good professionals.

Richard Reitz Smith, the head of the Book Arts program at Maine Media, is one of those professionals! He runs a smooth shop, with everything kept in perfect condition. Richard earned his art and graphic design degrees at Carnegie Mellon, and Temple University, respectively. I think he’s a wizard – calm, and with just the right amount of looking over my shoulder to see that I’m not getting into trouble. I little drip of ink on the carpet is met with a rag and solvent and the comment that it’s easy for that ink to travel on our shoes all over the studio. Whoops! And so I learn it.

My goal is to not be intimated by this press or this process – and Richard is my key to that goal.

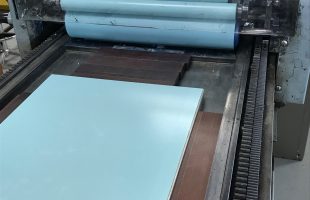

You see in the photograph the Vandercook press inked up. I am testing out colors for Objects of My Desire, and I am working out some monoprinting possibilities for some of the pages in the book. The color you see is a mix of a cyan blue, a transparent yellow, and lots of white. I’m printing it as both a second layer over a pale green, and by itself.

To get this far, I have to really memorize the steps towards preparing the press, locking up the plates in the press bed, mixing the ink, applying ink to the rollers, testing the printing quality by understanding the pressure of the rollers on the plate, and properly running the paper through the press.

On the other end of the process is a very lengthy clean-up! I go through my checklist of “to-do’s” and 45 minutes later the press is ready for another printer. So you can see that the primary reason for using the press is to print a many pages at a time, thereby making that clean-up a small part of your session. Even so, I’ll be at it for a month or two!